Ngokunemba okuphezulu kwesilinganiso, isivinini sokuphendula esisheshayo, ikhono eliqinile lokulwa nokuphazamiseka, uhlobo lwe-WLX-II ithuluzi lokulinganisa izinga lokushisa eliqhubekayo lensimbi encibilikisiwe linokwengamela kwesikhathi sangempela okuku-inthanethi kwezinga lokushisa lensimbi encibilikisiwe, okuyisilinganiso sakamuva sasekhaya esinembayo esiphezulu sezinga lokushisa lensimbi encibilikisiwe. umkhiqizo.Ngokusetshenziswa kwezitshalo ezihlukahlukene zensimbi, ukwethembeka nokuzinza komkhiqizo kuqinisekiswa ngokwanele.Impela ingumkhiqizo okahle ongangena esikhundleni seplatinamu rhodium thermocouple thermodetector.

Ibanga lokulinganisa: 700-1650 ℃

Ukungaqiniseki kwesilinganiso: ≤ ±3℃

Isikhathi sokuphila seshubhu lokushisa: ≥ amahora angama-24 (Amashubhu okushisa empilo ehlukene angakhiqizwa ngokuya ngesimo sendawo)

Izinga lokushisa lokusetshenziswa: 0-70℃(umtshina), 5-70℃ (iprosesa yesiginali)

Okukhiphayo okujwayelekile: 4-20mA/1-5V(ihambisana ne-1450-1650℃)

Amandla okushayela okukhiphayo: ≤400Ω(4-20mA)

Ukunemba komphumela:0.5

Ukunikezwa kwamandla:Ac220V±10V, 50HZ

Amandla: Iphrosesa yesiginali engu-30W nesibonisi esikhulu sesikrini esingu-25W.

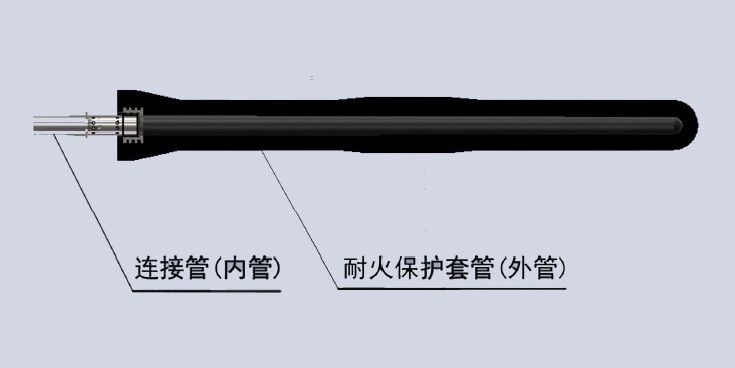

Ishubhu lezinga lokushisa liqukethe ishubhu elixhumayo kanye ne-casing evikela umlilo.Isikhwama sokuvikela esingangeni emlilweni sixhumene nomtshina ngeshubhu yokuxhuma.Ngokujula okuhlukene kwensimbi encibilikisiwe ye-tundish kanye nokugqwala kwensimbi encibilikisiwe kuya kushubhu lokushisa, ubude bezinga lokushisa bunemininingwane engu-1100mm, 1000mm no-850mm;ububanzi bunemininingwane engu-¢ ¢85mm kanye no-¢90mm, engenziwa ngokwezifiso ngokwesidingo sabasebenzisi.

I-temperature tube ifakwa ngqo ensimbi encibilikisiwe ukuze ibone izinga lokushisa;ukujula kokufakwa kuyadingeka kungabi ngaphansi kuka-280mm.Isignali yokulinganisa izinga lokushisa isuka ohlangothini lwangaphakathi ngaphansi kweshubhu elingaphandle;isikhathi sokuphendula sethuluzi ngokuyisisekelo silingana nesikhathi esidlulisa amandla ukusuka ohlangothini olungaphandle lweshubhu lokushisa ukuya ohlangothini lwangaphakathi.Ishubhu yokuxhuma isetshenziselwa ukuxhumana phakathi kweshubhu lokushisa kanye nomtshina.Ishubhu elingaphakathi ngokuyinhloko liwukuqeda intuthu ngaphakathi kweshubhu nokuqinisekisa ukuhlanzeka kwendlela yokukhanya.

| Into | Umzimba | Umugqa we-aluminium-magnesium-carbon slag | Umugqa we-Magnesium slag |

| I-Al2O3% | 54.8-56.2 | 61.7-62.2 | 22.7-23.3 |

| SiO2% | 7.0-8.0 | ||

| ZrO2% | |||

| MgO% | 8.5-9.0 | 41.4-42.0 | |

| FC% | 27.1-27.9 | 25.0-25.4 | 29.2-30.0 |

| Ukuminyana kwevolumu g/cmз | 2.46-2.53 | 2.71-2.79 | 2.48-2.52 |

| I-porosity ebonakalayo % | 11.5-14.8 | 11.4-13.8 | 11.8-12.8 |

| Amandla okuchotshozwa abandayo MPa | 20.9-32.9 | 21.2-27.6 | 20.7-26.7 |

| Amandla e-Flexural ekushiseni okuvamile kwe-MPa | 20.9-32.9 | 5.4-7.3 | 5.5-8.3 |

Umtshina uqukethe izingxenye ezibonayo, i-photoelectric converter, ulayini wokudlulisa isignali, ipulaki ephumayo kanye nepayipi lomoya opholile, njll. Itheminali yokufaka yomtshina ixhuma neshubhu elixhumayo leshubhu lokushisa;i-terminal ephumayo ixhuma neprosesa yesignali ngepulaki engu-6P;amatheminali okokufaka nokuphumayo axhunywe ngomugqa wokudlulisa isignali ovikelwe ipayipi lomoya opholile eliguquguqukayo.Isistimu yokubona idlulisa isignali yemisebe ye-infrared ethunyelwe kusukela phansi kweshubhu lezinga lokushisa ukuya kusiguquli se-photoelectric, bese isiguquli se-photoelectric siguqule isignali yokubona ibe isignali kagesi bese siyidlulisela kumprosesa wesignali ngomugqa wokudlulisa isignali.

Iphrosesa yesiginali iqukethe imojula yamandla, imojula yokucubungula isignali ye-analog, imojula yokuguqula i-analog-digital, imojula yokucubungula idijithali, imojula yokuxhumana kanye nemojula yokubonisa, njll. Isibonisi esikhulu sesikrini siqukethe imojula yamandla, imojula yokuxhumana kanye nemojula yokubonisa, njll.

Iphrosesa yesiginali inomsebenzi wokunxeshezelwa kwezinga lokushisa eliphindwe kabili, elingenza isinxephezelo esizenzakalelayo ekuphambukeni kokulinganisa okubangelwa izinga lokushisa lendawo yenzwa nezinga lokushisa lokusebenza kwethuluzi.

Iprosesa yesiginali ithola okokufaka kwesignali kagesi ngomtshina;Izinga lokushisa elilinganisiwe lensimbi encibilikisiwe libalwa yi-microprocessor ngokuya ngethiyori yemisebe ye-infrared futhi ikhonjiswe esikrinini.Okwamanje, idatha yezinga lokushisa lesikhathi sangempela ingaboniswa esikrinini esikhulu ngomsebenzi wokuxhumana.Isignali kagesi ingaphuma kukhompuyutha eyinhloko yokulawula isikhathi sangempela sokuqapha inqubo yokusakaza eqhubekayo.

1) Ngokusebenzisa lo mkhiqizo, singakwazi ukubona ngokuqhubekayo nangokunembile izinga lokushisa lensimbi encibilikisiwe ye-tundish nokuhlukahluka, sithatha izinyathelo kusenesikhathi ukuvimbela ukuphuma kwegazi noma ukuvala umlomo wombhobho wamanzi ngenxa yokushisa okuphezulu noma okuphansi kwensimbi encibilikisiwe, kunciphisa ukulahlekelwa ngenxa yokopha. -izimbobo eziphumayo neziqandisiwe, nesikhathi sokungenzi lutho ngenxa yezingozi, ngakho-ke kuthuthukisa izinga lokusebenza lomshini wokuphonsa.

2) Ngokusebenzisa lo mkhiqizo, singakwazi ukwazi umthetho wokushintsha we-tundish encibilikisiwe izinga lokushisa lensimbi.Ngokwalo mthetho woshintsho, singabeka phambili izidingo zepharamitha yezobuchwepheshe eziphusile kunqubo elandelayo, njengokwenza insimbi nokucwengisiswa.Ngokwenza lokhu, asikwazi nje ukwehlisa izinga lokushisa lokuthepha ngo-15 kuya ku-20℃, kodwa futhi siqinisekise uhlelo oluqinile lwenqubo, ukwandisa izinga lokuphatha kanye nokunemba kokulinganisa izinga lokushisa.

3) Ngesilinganiso sokushisa esinembile, lolu hlelo lungehlisa izinga lokushisa eliphakeme ngo-5 kuya ku-10 ℃.Ngokwehlisa izinga lokushisa okuphezulu singakwazi ukuthola indawo ebanzi ye-crystal equiaxed, sikhulule ukuhlukaniswa kwesikhungo se-cast blank, sigweme ngempumelelo amaphutha okuxega, umgodi wokushwabana nokuqhekeka, futhi sithuthukise ikhwalithi yensimbi;Okwamanje, ngokwehlisa izinga lokushisa okuphezulu singakwazi ukwandisa isivinini sokusakaza kanye nekhwalithi yensimbi.Izinqubo zohlelo lokusebenza zifakazela ukuthi le sistimu yokulinganisa izinga lokushisa ingakhuphula isivinini sokusakaza ngo-10% ngokwesilinganiso.